It is necessary to possess the skills and qualifications needed to work as a construction worker. There are many occupations within the construction industry. These classes will help to explain the different trades you can choose from in the construction sector. They will also teach you how to use project documents, plans, specifications, and green technologies. Additionally, you will be able practice with power tools as well as measuring instruments.

Overview of construction industry

There are many types of work in the construction industry. Some of these projects can be small or large and require wide-ranging services and expertise. There are also specialized companies whose primary focus is on one type of work. We will be looking at the role of different types and how they differ from other sectors in the construction industry.

Although the overall growth rate of the construction industry has been slow, it still faces many challenges. An increasing population puts more pressure on infrastructure and housing.

Opportunities for career advancement in the industry

There are many career options for those who are interested in the construction sector. There are many routes to getting in on the construction industry, whether you are an experienced professional looking for a job or someone who is just starting out. The Bureau of Labor Statistics predicts that construction will grow by approximately 10 percent in the next ten-years, making it a top career choice. The field is becoming more diverse as women and minorities are choosing to work here.

The construction industry offers a variety of career options for those with an engineering or construction degree. You could be a project manager if you are a problem solver. These professionals oversee all aspects of a construction project, including planning, budgets, and coordination. They should have exceptional problem-solving abilities and strong leadership skills. A degree in civil engineering or construction management is required. Many project managers start out as construction engineers.

You need to have the right skills to work in this industry

You will need a variety of skills to perform a construction job. A construction job requires you to be able read and calculate dimensions accurately. You will also need to have basic math and English language skills. Effective communication is essential when working in a construction environment.

The construction industry requires specific skills, such as bricklaying, carpentry, or pouring cement. Other skills include using specific equipment or putting up drywall. In addition, the ability to think critically and work under tight deadlines is critical for any construction position. To succeed in the construction sector, you'll need a range of soft abilities, such as communication skills, conflict management, and collaboration.

The industry requires that you have the right educational qualifications

Educational requirements for entry into the construction industry vary depending on the specific type of occupation you'd like to pursue. Apprenticeship programs and college courses can help you gain the knowledge and skills necessary to succeed in this industry. OSHA certification courses are also available to help you understand safety regulations. You can also get specialty certifications that train you for specific types of work. These courses are available online, or can be done in person.

An associate's or certificate in construction management can be earned. Construction management programs typically take two years to complete, and will give you the practical skills needed to succeed in the industry. You may also opt for a program that covers the business side.

FAQ

Six Sigma is so popular.

Six Sigma is easy and can deliver significant results. Six Sigma provides a framework to measure improvements and allows companies to focus on the most important things.

What are the steps involved in making a decision in management?

Managers face complex and multifaceted decision-making challenges. It involves many factors, such as analysis and strategy, planning, execution, measurement, evaluation, feedback etc.

Remember that people are humans just like you, and will make mistakes. This is the key to managing them. There is always room to improve, especially if your first priority is to yourself.

We explain in this video how the Management decision-making process works. We discuss different types of decisions as well as why they are important and how managers can navigate them. These topics are covered in this course:

It seems so difficult sometimes to make sound business decisions.

Complex systems are often complex and have many moving parts. Their leaders must manage multiple priorities, as well as dealing with uncertainty.

The key to making good decisions is to understand how these factors affect the system as a whole.

This requires you to think about the purpose and function of each component. It is important to then consider how the individual pieces relate to each other.

You should also ask yourself if there are any hidden assumptions behind how you've been doing things. If you don't have any, it may be time to revisit them.

If you're still stuck after all this, try asking someone else for help. They may see things differently from you and have insights that could help you find a solution.

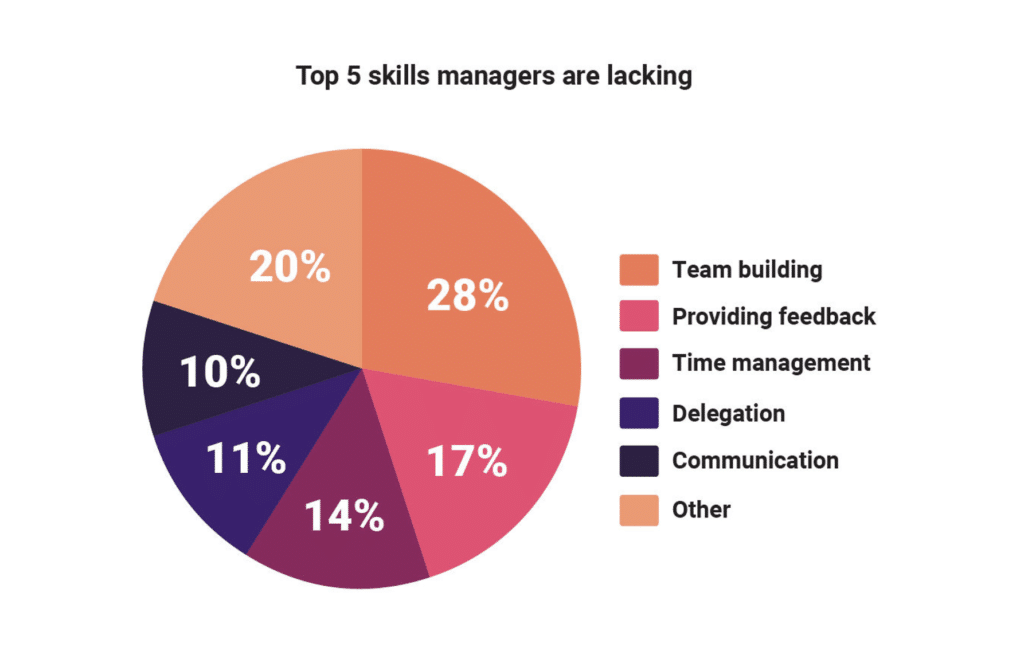

How do you effectively manage employees?

Effectively managing employees requires that you ensure their happiness and productivity.

It means setting clear expectations for them and keeping an eye on their performance.

Managers need clear goals to be able to accomplish this.

They need to communicate clearly with staff members. And they need to ensure that they reward good performance and discipline poor performers.

They will also need to keep records about their team's activities. These include:

-

What was the result?

-

How much work did you put in?

-

Who did it and why?

-

How did it get done?

-

Why it was done?

This data can be used to evaluate and monitor performance.

Which kind of people use Six Sigma

People who have worked with statistics and operations research will usually be familiar with the concepts behind six sigma. Anyone involved in business can benefit.

Because it requires a high level of commitment, only those with strong leadership skills will make an effort necessary to implement it successfully.

Statistics

- 100% of the courses are offered online, and no campus visits are required — a big time-saver for you. (online.uc.edu)

- The BLS says that financial services jobs like banking are expected to grow 4% by 2030, about as fast as the national average. (wgu.edu)

- Our program is 100% engineered for your success. (online.uc.edu)

- Hire the top business lawyers and save up to 60% on legal fees (upcounsel.com)

- The profession is expected to grow 7% by 2028, a bit faster than the national average. (wgu.edu)

External Links

How To

How can you use the Kaizen method?

Kaizen means continuous improvement. The term was coined in the 1950s at Toyota Motor Corporation and refers to the Japanese philosophy emphasizing constant improvement through small incremental changes. It is a process where people come together to improve their processes.

Kaizen is one of the most effective methods used in Lean Manufacturing. Kaizen is a concept where employees in charge of the production line are required to spot problems during the manufacturing process before they become major issues. This increases the quality of products and reduces the cost.

Kaizen is an approach to making every worker aware and alert to what is happening around them. So that there is no problem, you should immediately correct it if something goes wrong. So, if someone notices a problem while working, he/she should report it to his/her manager.

Kaizen is based on a few principles. Start with the end product, and then move to the beginning. If we want to improve our factory for example, we start by fixing the machines that make the final product. We then fix the machines producing components, and the machines producing raw materials. Finally, we repair the workers who are directly involved with these machines.

This is known as "kaizen", because it emphasizes improving each step. We finish fixing the factory and then go back to the beginning. This continues until we achieve perfection.

Before you can implement kaizen into your business, it is necessary to learn how to measure its effectiveness. There are several ways to determine whether kaizen is working well. Another method is to see how many defects are found on the products. Another method is to determine how much productivity has improved since the implementation of kaizen.

You can also find out if kaizen works by asking yourself why you decided to implement it. Was it just because it was the law or because you wanted to save money? You really believed it would make you successful?

Let's say you answered yes or all of these questions. Congratulations! You're ready to start kaizen.