A strategic plan for managing change should include key elements. These include communication, adaptability, and SWOT analysis. A detailed evaluation of the current materials is required to start. Once you have this information, you can begin planning your change management strategy. Next, determine who you are targeting and how you will communicate with them.

The key elements of a strategy for managing change are:

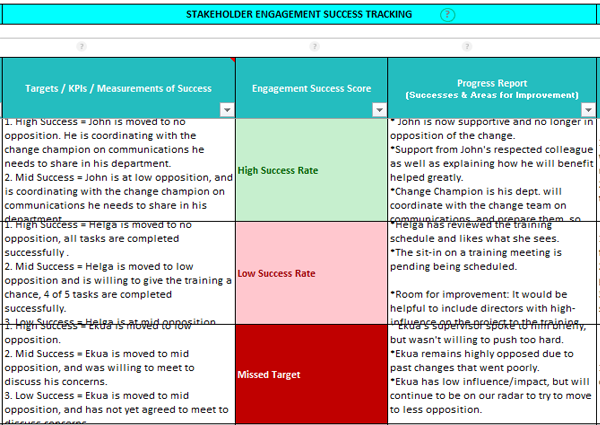

A strategic change management plan has several elements, and a key element is stakeholder engagement. This involves engaging key stakeholders including employees to discuss why a change in the process. The process involves communicating the benefits of a different way of doing things. The plan should provide a baseline and be quantifiable so that it can be used to evaluate the success of any change.

It should list the resources necessary to carry out the change. The process of change management is similar to the development of a general plan for a project. After the planning phase, the roadmap will be documented. With a change management plan, scope creep is minimized and risks are minimized. It should be able to handle unexpected obstacles and roadblocks. It should also allow for unexpected problems to be addressed.

Adaptability

The concept adaptive change describes the ability of an organisation to rapidly evolve and adapt as needed. This involves creating flexible structures and dispersed decision-making rights. The process starts with identifying the company's needs, and then selecting, amplifying and refining a solution. This approach requires that the organization creates an environment that encourages communication and constructive conflict as well as risk-taking.

Being adaptable requires that an organization recognize signs of change in the environment and be able decode them quickly to react. Companies must be able quickly to change their strategy, adjust their business models, or change the information landscape.

Communication

Communication is a key aspect of strategic management of change. Employees should be able communicate their opinions. Communicating your changes and policies through the appropriate channels will ensure that they are fully committed to the new direction of business. There are many different ways to communicate your changes. It is important that you know the preferred channels of communication for your employees in order to make sure they remember what you said.

Video content is an option depending on how the change will be explained. A dedicated intranet space for change-related information can also be an effective tool. This space can house fact sheets and training materials as well discussion forums and employee feedback.

SWOT analysis

SWOT analysis is a tool that can be used by organizations to assess their vulnerabilities and potential for change. It helps identify what factors make an organization more vulnerable to external threats like bad debt and cash flow problems. It can also be used to determine the impact of small market changes on a company's bottom-line. Albert S. Humphrey is commonly credited with creating this type of analysis. However, this debate has continued and the TOWS Matrix has been claimed to have been its original creator.

A SWOT analysis can also be used to assess an organization's capabilities to meet its strategic objectives. It is an excellent tool for developing a big picture perspective and detailed strategic evaluation. The SWOT framework was developed as a result of research conducted by the Stanford Research Institute, in the 1960s. This research was ordered by several Fortune 500 businesses. Its authors were Robert Stewart, Marion Dosher and Albert Humphrey. Du Pont also completed a SWOT analysis. It was this analysis that paved the way for corporate planning. Soon after, every Fortune 500 corporation had a corporate Planning Manager. Long-range strategic plan associations across the USA were established.

Employee engagement

Strategic change management is only possible if employees are engaged. It is essential to ensure that employees are engaged in the implementation of change. Without it, it can prove difficult, reduce adoption, and increase attrition. Organizations need to take proactive steps in order to prevent employees from becoming disengaged during the change process. Engagement can be defined as employees' overall emotional response to their employer and job. This will then translate into their behaviours at work.

Managers need to get to know their employees and understand them as people in order for high engagement. Managers must understand their employees, and give them opportunities that will allow them to express their talents. They need to discuss the importance of each person in the team and the unique contribution they make to the company. They must also coordinate their work with the talents of each member. This allows them to maximize the value each employee brings the company.

FAQ

What are the top management skills?

Any business owner needs to be able to manage people, finances, resources and time. These include the ability and willingness to manage people, finances as well resources, time and space.

These skills are necessary for setting goals and objectives as well as planning strategies, leading groups, motivating employees and solving problems.

As you can see there is no end to the number of managerial tasks.

How do you define Six Sigma?

Six Sigma is well-known to those who have worked in operations research and statistics. It can be used by anyone in any business aspect.

It is a commitment-intensive task that requires strong leadership skills.

What is the difference between project and program?

A project is temporary; a program is permanent.

A project has usually a specified goal and a time limit.

It is often done in a team that reports to another.

A program often has a set goals and objectives.

It is usually done by one person.

Statistics

- This field is expected to grow about 7% by 2028, a bit faster than the national average for job growth. (wgu.edu)

- The average salary for financial advisors in 2021 is around $60,000 per year, with the top 10% of the profession making more than $111,000 per year. (wgu.edu)

- Our program is 100% engineered for your success. (online.uc.edu)

- The profession is expected to grow 7% by 2028, a bit faster than the national average. (wgu.edu)

- Your choice in Step 5 may very likely be the same or similar to the alternative you placed at the top of your list at the end of Step 4. (umassd.edu)

External Links

How To

How can you use the Kaizen method?

Kaizen means continuous improvement. This Japanese term refers to the Japanese philosophy of continuous improvement that emphasizes incremental improvements and constant improvement. It's a process where people work together to improve their processes continuously.

Kaizen is one method that Lean Manufacturing uses to its greatest advantage. The concept involves employees responsible for manufacturing identifying problems and trying to fix them before they become serious issues. This way, the quality of products increases, and the cost decreases.

Kaizen is a way to raise awareness about what's happening around you. To prevent problems from happening, any problem should be addressed immediately. If someone spots a problem while at work, they should immediately report it to their manager.

There are some basic principles that we follow when doing kaizen. Always start with the end product in mind and work our way back to the beginning. For example, if we want to improve our factory, we first fix the machines that produce the final product. First, we fix machines that produce components. Next, we fix machines that produce raw material. Then, we fix those who work directly with the machines.

This is known as "kaizen", because it emphasizes improving each step. Once the factory is fixed, we return to the original site and work our way back until we get there.

Before you can implement kaizen into your business, it is necessary to learn how to measure its effectiveness. There are many ways to tell if kaizen is effective. Another way to determine if kaizen is working well is to look at the quality of the products. Another method is to determine how much productivity has improved since the implementation of kaizen.

If you want to find out if your kaizen is actually working, ask yourself why. Was it just because it was the law or because you wanted to save money? It was a way to save money or help you succeed.

Let's say you answered yes or all of these questions. Congratulations! You're ready to start kaizen.